What can recycled silk look or feel like?

What properties can be achieved by finishing, grafting, forming ?

Designing futures that ensure a continued, thriving survival in the anthropocene is what drives this project. In order to achieve a higher level of resilience, new processes, materials, resource-efficient energy use as well as resource-efficient raw material extraction are required.

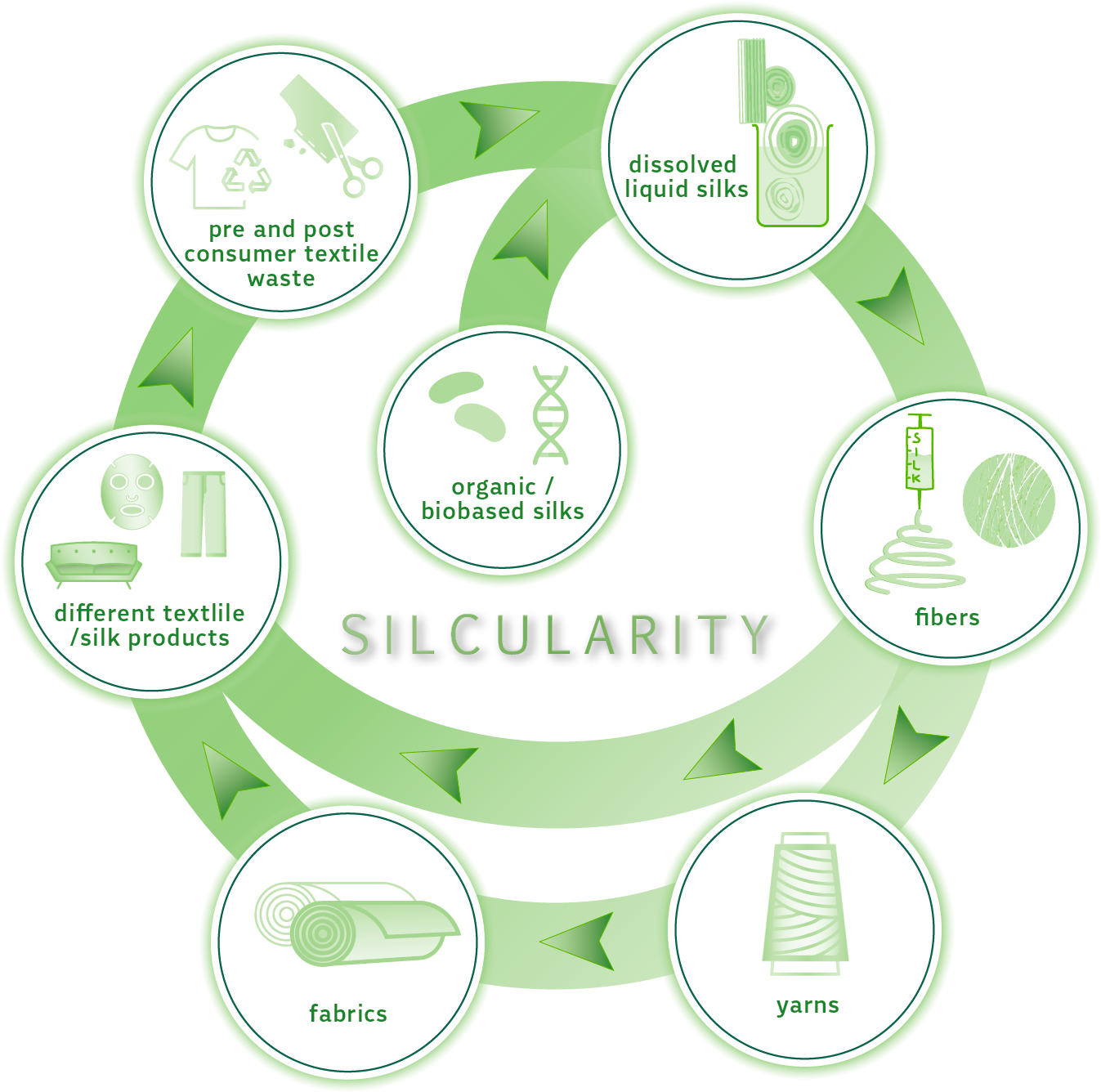

Silcularity was first developed within the electro spinning focused residency "living layers" at the BioLab at BURG Giebichenstein in winter 21/22. In the course of this residency, the chemical structure of silk fibrin was investigated, later on dissolved and finally tested for possible usage. This process led to the idea of using the dissolving process not only for electro spinning, but also to dissolve old or unused silk fabrics in order to achieve a circular use of the valuable material. Eversince the concept of ‚silcularity' was brought to life, various recycling applications were achieved through the techniques of dissolving, re-hardening and grafting.

To test the feasibility of ‚silcularity‘, silk fibroins from cocoons, mixed fabrics as well as production residues were dissolved, using a natural solvent. Processing and curing the liquid recycled fibroin (ReFib) into various forms finally proved the assumption that electro spinning can be used to create new textiles from nano fibers. Since the original fibroin coloration is retained, ReFib can also be used for finishing and coloring fabrics and surfaces.

silcularity was continued in the bachelorthesis "ReFib - Recyclingfibroin as a textile finish" in Januar 2023. When selecting possible processes for dissolving and grafting fibroins, the focus was on substances and processes that were as energy-saving and harmless as possible. Thus, an environmentally friendly solvent was chosen. For the grafting of fibroin to textile fibers and surfaces, the decision feld on wool. Based on the sources and in discussions with colaborating scientists, the long-term binding of fibroin to wool does not nessesary require an additional crosslinker. In addition, the dyes of silk and wool are identical, thus ensuring that the silk color can also be transferred.

In order to check whether the bonding of ReFib really works, fabrics and knitwear were produced in addition to technical measuring methods. On a cotton warp, it was possible to create mixed fabrics in different shapes and woolyarns. As can be seen in the results, it is mainly the wool components that are dyed, while the cotton appears to remain unchanged.

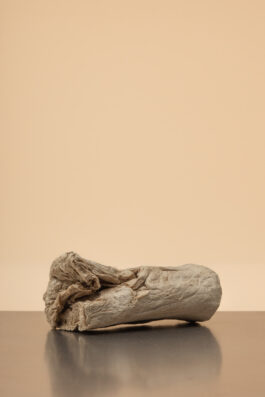

How can ReFib be shaped?

The solvent dissolves only the silk in blended fabrics, cellulose remains unchanged. Fabrics provided by Barth & Könenkamp

Can this process be transferred to

other materials?